| Properties | Unit | Teat Typical Value | |||

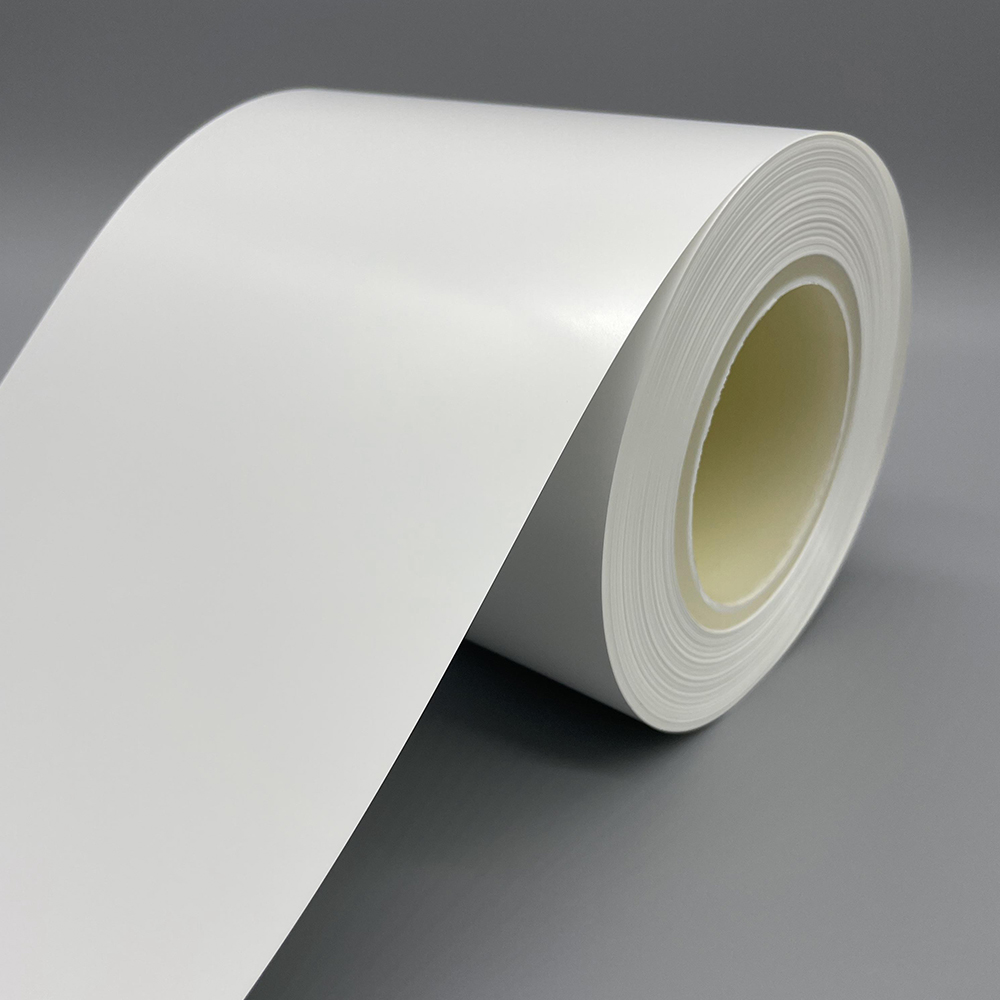

| Total Thickness | μm | 150±10 | |||

| Density | g/cm3 | 1.24 | |||

| Tensile Strength | MD | Mpa | 60 | ||

| TD | 105 | ||||

| Elongation at Break | MD | % | 70 | ||

| TD | 50 | ||||

| Thermo Shrinkage | 85℃ | MD | % | 0.2 | |

| 30min | TD | 0 | |||

| Whiteness | % | 95.5 | |||

| YI E313 | 0.8 | ||||

| Glossness | 45° | % | 25 | ||

| Reflectivity | 450nm | % | 96.2 | ||

| 550nm | 96.1 | ||||

| 650nm | 96 | ||||

| Weatherability | High temperature and humidity test(65×90%RH×500hr) | ΔRf(550nm)<2 | |||

| High temperature test(85℃×500hr) | |||||

| Low temperature test(-20℃×500hr) | |||||

| Cold and hot cycle test(-20℃×1hr~85℃×1hr) | |||||

| Uvioresistant yollowing test | ΔRf(550nm)<2 | ||||

| ΔYI<3 | |||||

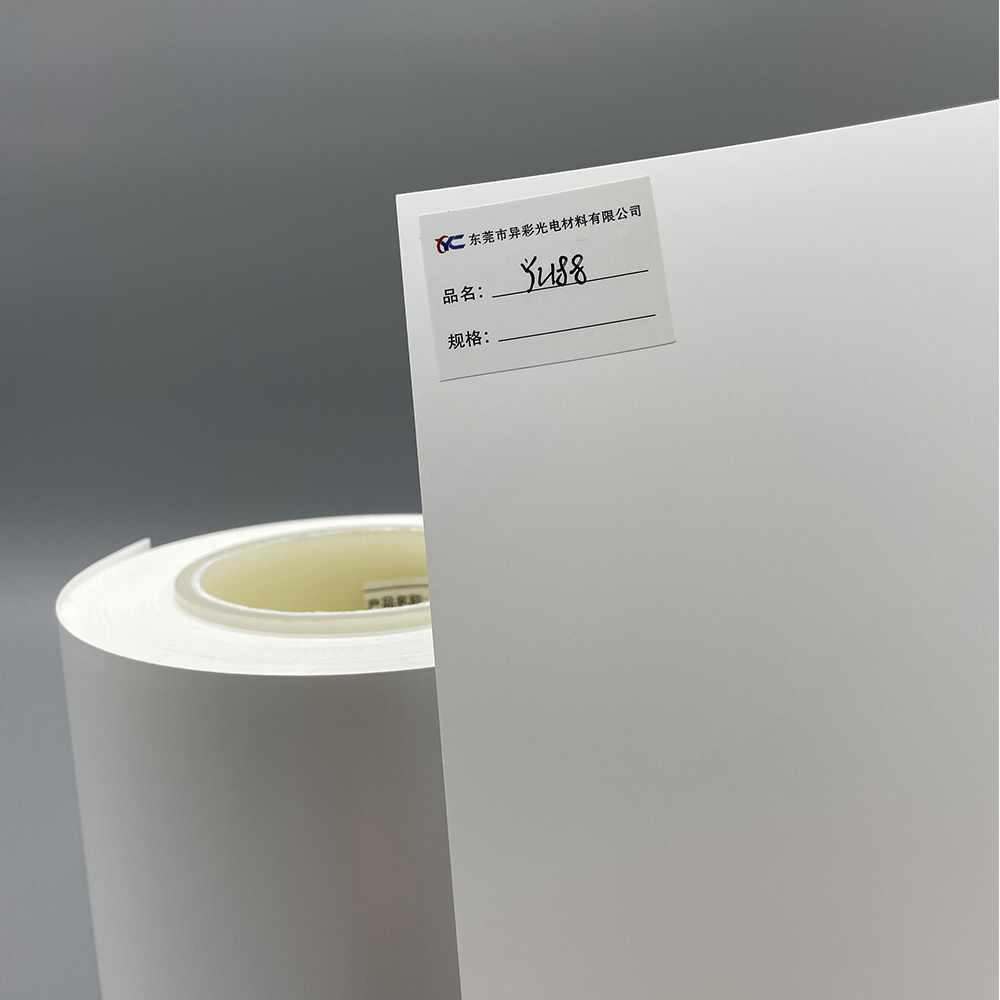

| Visual Inspection | / | / | One side bright /one side matt | ||

| Remark: MD is the machine direction, TD is the transverse direction | |||||

| *Typical Values are not guaranteed | |||||

Certificate GB/T13542-2009